Macrofouling is a widespread problem in seawater cooling disinfection applications.

Chlorine Dioxide (ClO2 ) has emerged as a go-to solution for macrofouling control due to its superior efficiency and environmental performance compared to traditional treatments such as electrochlorination and bromine-based treatments.

While ClO2 is more expensive than most traditional treatments, its economic benefits outweigh the additional biocide spend. Even minor improvements in cooling performance (ΔT) and plant uptime/lifespan can lead to significant cost savings.

Scotmas, a company that has long pioneered ClO2 use, has developed a new dosing technology called Active Dosing™. This technology is fitted to all our ClO2 systems applied for Seawater Cooling Applications.

Unlike a simple “constant dose” or “on-off” methodology, Active Dosing™ takes into account the unique seasonal and tidal patterns at the installed location. It ensures that a minimum level of biocide is used to remove the target organism from seawater intake lines. Our biologists who designed Active Dosing™ integrated it with ClO2 to provide a cost-effective, environmentally friendly response to most seawater macrofouling challenges.

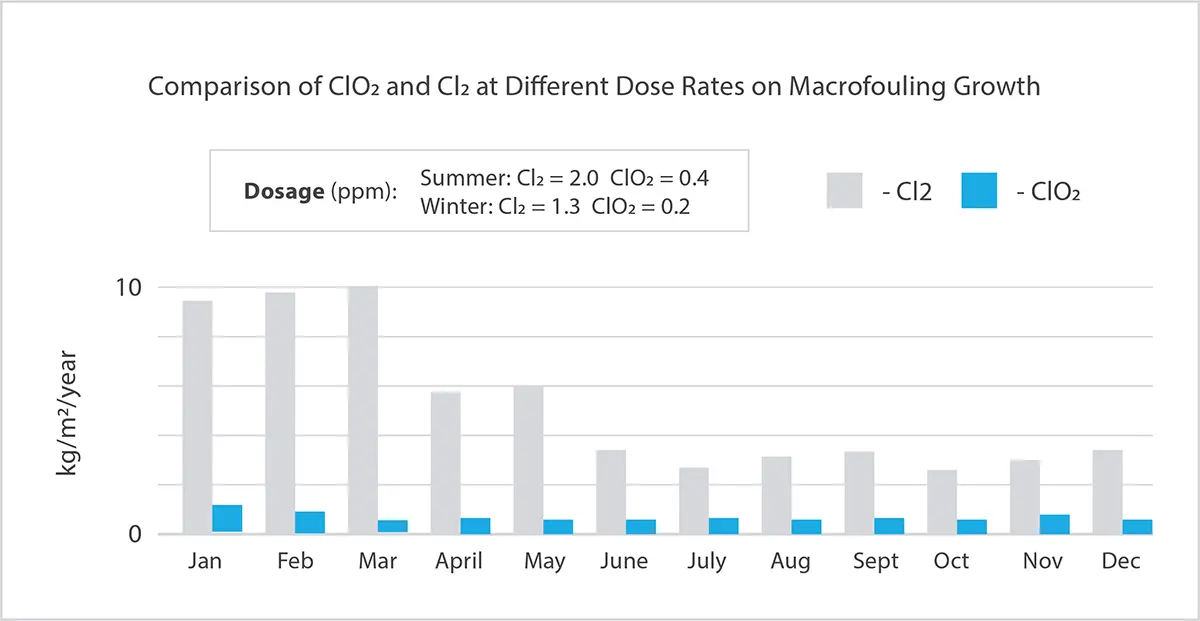

Comparison of ClO2 and Cl2 at Different Dose Rates on Macrofouling Growth

Targeting Macrofoulants

Scotmas Active Dosing™ systems are primarily designed to target macrofoulants such as molluscs, oysters, barnacles, and other bivalves.

These organisms are generally able to detect low levels of biocide and quickly enter a “closed” or anaerobic state that is more resistant to treatment than when they are “open” and feeding (aerobic state). Many bivalves can remain in this state for several days, and thus, the chemical doses required are significantly higher to remove them from the system.

Active Dosing™ technology carefully synchronises the quantity and time of the biocidal treatment to the bivalve’s feeding patterns. It also uses the fast-acting, low-residual effects of ClO2 to “exhaust” the bivalves in a short space of time. As a result, lower doses of biocide can be used to remove them, which leads to lower overall chemical consumption and fewer environmental pollutants released into the environment.

ClO2 – The Superior Choice

Chlorine Dioxide remains the superior choice for macrofouling control in seawater cooling disinfection applications. Active Dosing™ technology is a cost-effective, environmentally friendly response to most seawater macrofouling challenges. It has proven to be an effective way to minimise the use of biocides while still achieving optimal results.

If you’re facing macrofouling challenges in your seawater cooling disinfection applications, consider switching to Chlorine Dioxide with Active Dosing™ technology. This cost-effective, environmentally friendly solution has proven to be highly effective in minimising the use of biocides while still achieving optimal results.

Contact Scotmas today to learn more about our ClO2 systems and how they can help you improve cooling performance and plant uptime while reducing chemical consumption and environmental pollutants.

Don’t let macrofouling become a major headache for you – take action now and switch to Scotmas.