With the challenges of increasing water scarcity driven by population growth, climate change, and excessive extraction of freshwater resources, desalination has become a promising solution to meet the water needs of millions.

Desalination offers a seemingly endless supply of fresh water by converting seawater into potable water. However, the process has challenges, including high energy consumption, operational costs, and environmental concerns.

With over 70% of the Earth’s surface covered by water, it is easy to assume that plenty of water is available. Only about 2.5% of this water is freshwater, and less than 1% is accessible for human use. As freshwater sources become increasingly strained, particularly in arid and semi-arid regions, desalination offers a viable alternative by tapping into the vast reserves of seawater.

Countries in the Middle East, North Africa, and parts of Asia, where freshwater is scarce, have already embraced desalination as a critical part of their water supply strategy. The technology has enabled these regions to meet the growing water demand, supporting agricultural production, industrial processes, and urban populations. As water scarcity becomes a global concern, the interest in desalination is expanding to other parts of the world.

Challenges of Desalination (SWRO)

While desalination provides a reliable source of freshwater, the process is energy-intensive and costly. Traditional desalination methods, such as reverse osmosis and distillation, require significant amounts of energy to remove salts and other impurities from seawater. This high energy demand translates into elevated operating costs, making desalinated water more expensive than other water sources.

Additionally, the desalination process generates brine, a concentrated salt solution often discharged into the ocean. This brine can harm marine ecosystems, including increased salinity levels and potentially harm aquatic life. Managing these environmental impacts is crucial for the widespread adoption of desalination technology.

Scotmas’ Contribution to Desalination (SWRO) Efficiency

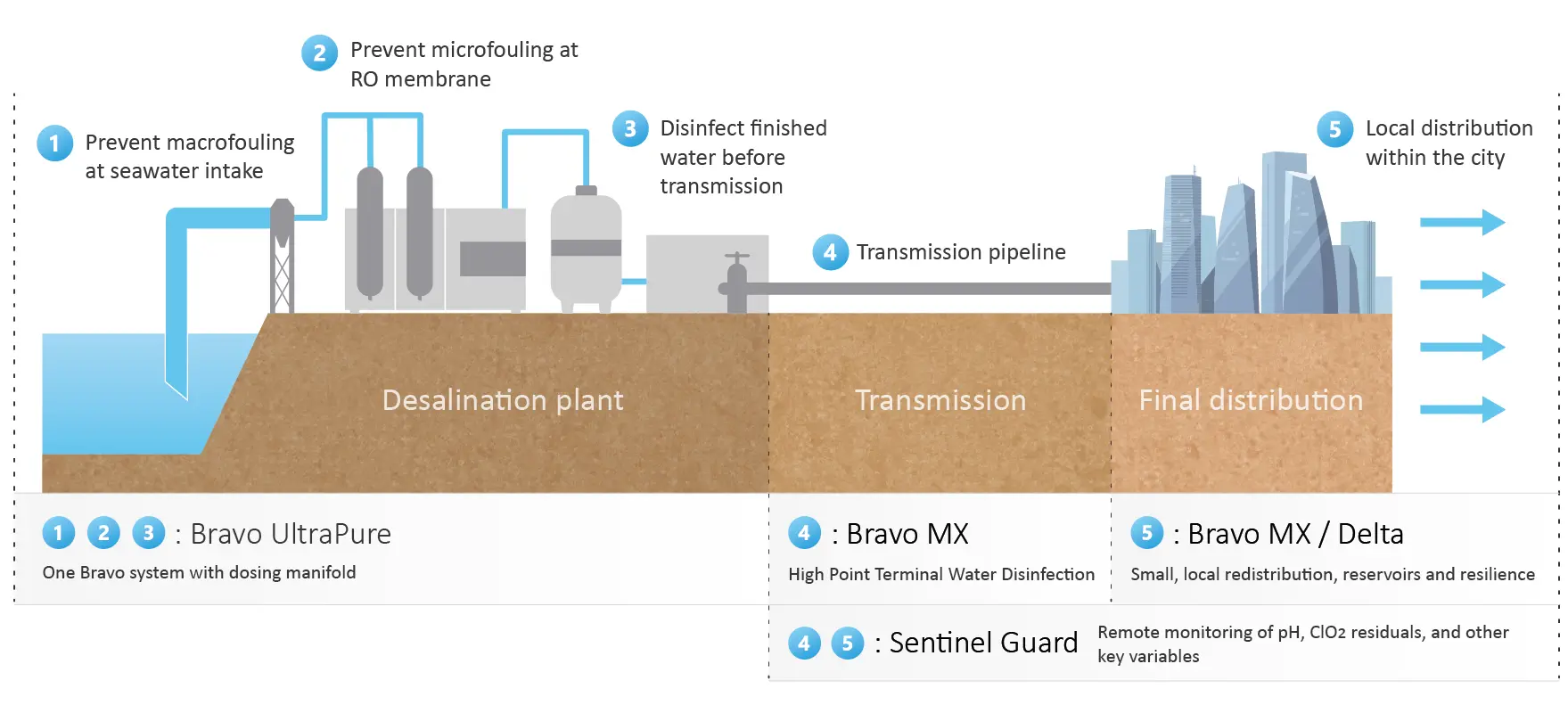

Innovations in desalination technology are essential to address these challenges. Scotmas, a leader in water treatment solutions, has developed Ultra-Pure Chlorine Dioxide-based technology that plays a vital role in increasing the efficiency of the desalination process. Chlorine Dioxide (ClO₂) is a powerful oxidant and disinfectant used to treat water at various stages of the desalination process.

Enhancing Efficiency: Scotmas’ Ultra-Pure Chlorine Dioxide technology is particularly effective in pre-treatment processes, where it helps control biofouling and the accumulation of microorganisms, plants, and algae on surfaces. Biofouling is a common issue in desalination plants, especially in reverse osmosis systems, where it can reduce membrane efficiency and increase energy consumption. By preventing biofouling, Scotmas’ technology ensures that desalination plants operate optimally, reducing the energy required to produce fresh water.

Enhancing Efficiency: Scotmas’ Ultra-Pure Chlorine Dioxide technology is particularly effective in pre-treatment processes, where it helps control biofouling and the accumulation of microorganisms, plants, and algae on surfaces. Biofouling is a common issue in desalination plants, especially in reverse osmosis systems, where it can reduce membrane efficiency and increase energy consumption. By preventing biofouling, Scotmas’ technology ensures that desalination plants operate optimally, reducing the energy required to produce fresh water.

Reducing Operating Costs: Ultra-Pure Chlorine Dioxide also translates into significant cost savings. Desalination plants can lower their operating costs by maintaining clean membranes and reducing the need for frequent cleaning or replacement. Additionally, the technology reduces the demand for other chemical treatments, further cutting expenses and simplifying the water treatment process.

Minimising Environmental Impact: Scotmas’ technology also minimises desalination’s environmental impact. Chlorine Dioxide is a selective oxidant, meaning it effectively targets harmful organisms without producing large amounts of harmful byproducts. This reduces the chemical load on marine environments, making desalination more environmentally friendly. The technology’s efficiency in controlling biofouling leads to less energy consumption, indirectly reducing desalination plants’ carbon footprint.

Scotmas Bravo Ultra-Pure Chlorine Dioxide (BUP)

The Bravo Ultra-Pure (BUP) is our unique, patented Chlorine Dioxide generation system, designed to produce the purest Chlorine Dioxide solution.

The Bravo Ultra-Pure separation technologies remove and recycle excess acids and reaction byproducts from the Chlorine Dioxide stream. They also allow for maintaining desalination membrane osmotic pressure at design levels, keeping energy consumption constant, increasing membrane longevity, and significantly reducing CIP cleaning.

The Future of Desalination (SWRO)

As desalination technology evolves, it is becoming an increasingly viable solution to address global water scarcity. Integrating innovative technologies, such as Scotmas’ Ultra-Pure Chlorine Dioxide, is crucial in overcoming the challenges associated with desalination. Enhancing efficiency, reducing costs, and lessening the environmental impact make desalination a more sustainable and accessible option for providing clean water to water-stressed regions.

Looking ahead, the role of desalination is expected to grow as more countries seek to secure their water supplies in the face of climate change and population growth. Continued research, development, and adoption of cutting-edge technologies will be essential in making desalination a cornerstone of global water management strategies.

A Promising Solution

Desalination offers a promising solution to the world’s growing water challenges. It can transform seawater into a lifeline for millions of people. Addressing the associated energy, cost, and environmental challenges is crucial to fully realising this potential.

Scotmas’ Ultra-Pure Chlorine Dioxide-based technology is making significant strides in this direction, enhancing the efficiency of desalination processes, reducing operating costs, and minimising environmental impacts. As the world continues to search for sustainable solutions to water scarcity, innovations like these will ensure that desalination can truly quench our thirst.

Contact our team on +44 (0)1573 226901 or email us at enquiries@scotmas.com to learn more about how our Chlorine Dioxide technology can help improve the effectiveness of desalination operations.