Biofilm, an often overlooked concern, can cause problems in various areas of hatchery operations, affecting both the well-being of livestock and the efficiency of processes.

In this article, we will look into the locations where biofilm tends to accumulate within hatcheries and explore effective strategies for its prevention.

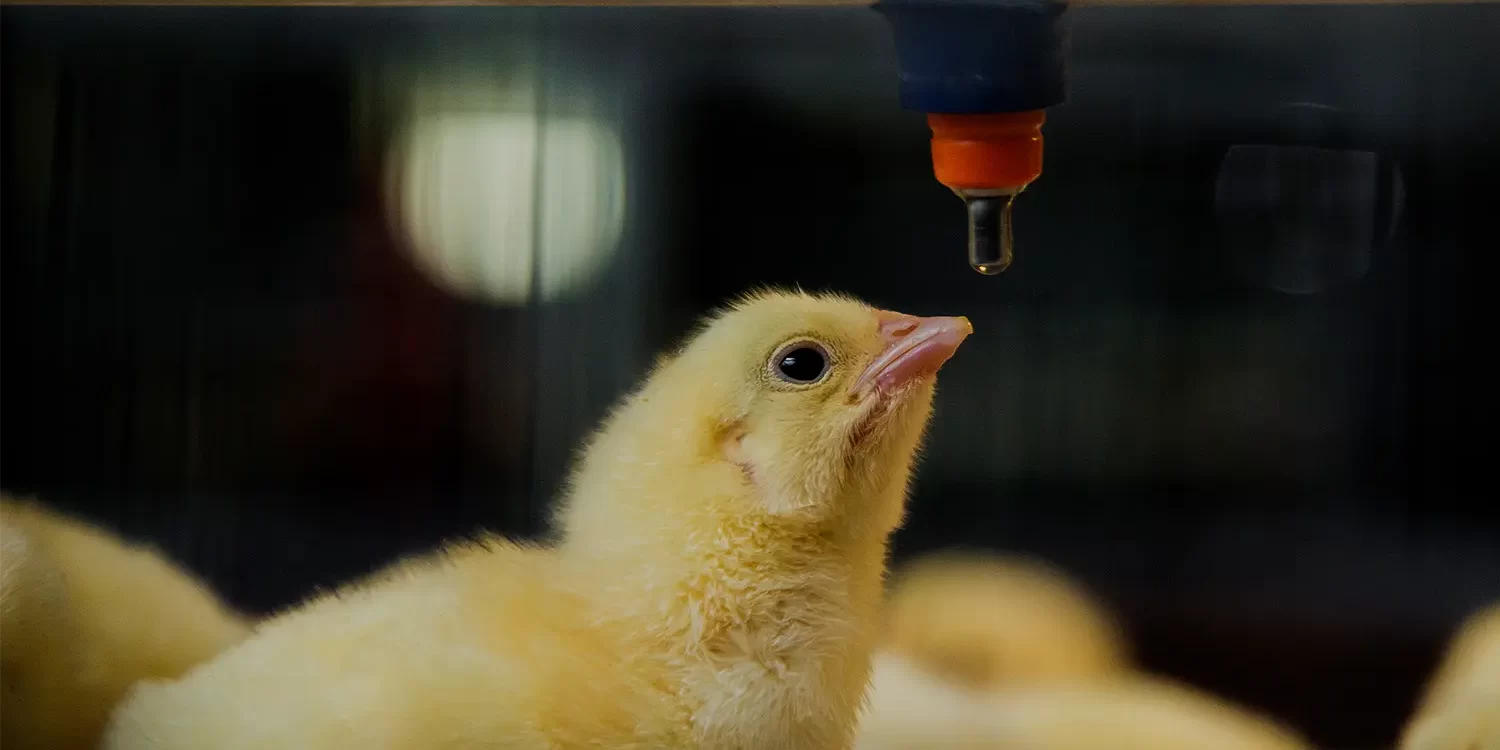

Drinking water, essential for the well-being of livestock, is susceptible to contamination by airborne pathogens. The rapid multiplication of pathogens in ideal conditions—such as those found in hatcheries—underscores the need for continuous water treatment. Traditional biocides like chlorine fall short in tackling biofilm. Chlorine Dioxide, a powerful oxidising biocide, can destroy biofilm and provide a clean water distribution system.

Humidification Water in Hatcheries

Biofilm Management in Hatchery

Controlling spores and fungi buildup in hatcheries calls for regular fogging with Chlorine Dioxide. This practice, especially effective in larger buildings, ensures microbial control and eliminates noxious odours. Advanced automated systems with timer controls enhance protection and contribute to improved air quality.

Cooling Water in Hatcheries

Cooling water, when left untreated, becomes a breeding ground for bacteria, exposing both staff and chicks to significant risks. Chlorine Dioxide stands out by removing biofilm, unlike chlorine and other water treatment products, ensuring optimal cooling performance and reducing health hazards.

Year-Round Protection from Biofilm

Air handling systems, often neglected in routine cleaning, become breeding grounds for pathogens. Chlorine Dioxide, applied at the system’s entrance via misting nozzles, ensures year-round protection against biofilm development, improving chick quality and reducing staff absence due to air-borne contaminants.

Egg Handling Systems in Hatcheries

Sanitising eggs and incubation equipment is critical for successful hatchery management. Chlorine Dioxide proves to be a safer and more effective alternative to formaldehyde in egg sanitation. Whether in egg handling, incubators, or hatchers incorporating Chlorine Dioxide ensures a pathogen-free environment and enhances yield results.

Equipment and Personnel Hygiene in Hatcheries

Utilising Scotmas’ Chlorine Dioxide-based products extends from maintaining equipment hygiene to ensuring personnel cleanliness. Whether using Scotmas Hand Gel for personal hygiene or utilising it as a fogging agent for general room sanitation and rodent control, these practices emphasise our commitment to safety, effectiveness, and environmental responsibility.

Effective hatchery management goes beyond routine tasks, addressing biofilm challenges in every aspect of operation. Chlorine Dioxide, with its diverse applications, emerges as a versatile solution, ensuring a clean and pathogen-free environment.

For personalised guidance and solutions tailored to your hatchery’s needs, reach out to Scotmas today. Optimise your hatchery hygiene, protect your livestock, and enhance overall operational efficiency with our advanced solutions.